Hello, my name is Allen, and for over a decade, I’ve been at the heart of big bag manufacturing here in China. I’ve seen our seven production lines ship countless containers to partners in the USA, Europe, and Australia. I understand the world of bulk material handling isn’t just about a bag; it’s about trust, efficiency, and the bottom line. This comprehensive guide is for procurement leaders like Mark Thompson—decisive, knowledgeable, and always looking for that perfect balance of quality and value. If you’ve ever dealt with shipment delays, communication gaps, or questioned the authenticity of a supplier’s certification, this article is for you. We will dive deep into the world of FIBC bags, specifically the often-overlooked but highly efficient 1 and 2 loop varieties. You’ll gain a factory-insider’s perspective on their construction, uses, and how to choose the right FIBC for your needs, ensuring your supply chain is as robust and reliable as the products you sell.

What Exactly is a Flexible Intermediate Bulk Container (FIBC)?

Let’s start with the basics. A Flexible Intermediate Bulk Container, more commonly known as bulk bags or a FIBC bag, is an industrial container made of flexible fabric that is designed for storing and transporting dry bulk materials, such as sand, fertilizer, plastic granules, or seeds. Think of it as a massive, durable sack that can hold anywhere from 500 to 2000 kilograms (about 1100 to 4400 pounds) of product. These aren’t your average sacks; they are precision-engineered pieces of equipment. The primary material we use polypropylene in making FIBC bags, a thermoplastic polymer that is incredibly strong, resistant to fatigue, and lightweight.

The term "intermediate" is key here. These bags are designed to handle weights that are more than a person can carry but less than a full-scale intermodal container. This makes them the perfect solution for businesses in agriculture, mining, and chemicals that need to move large quantities of product efficiently. The usefulness of FIBC bags lies in their ability to streamline logistics, reduce packaging waste, and protect the product within. A single FIBC bag can replace a pallet of smaller sacks, saving significant time and labor during loading and unloading.

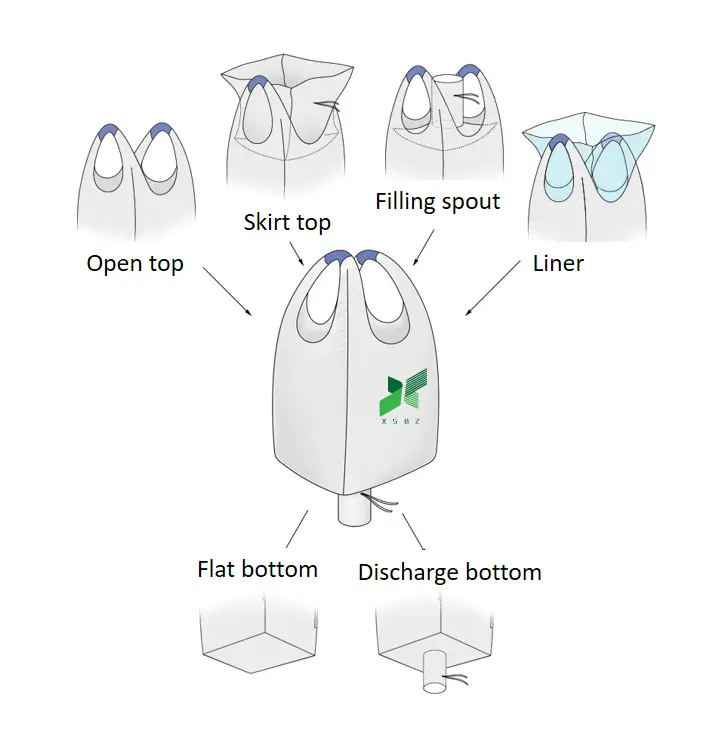

The design of a FIBC bag is more complex than it appears. It includes the main body, the top opening (like a spout or open duffle), the bottom discharge mechanism, and, most importantly, the lifting loops. The number and style of these loops are critical, as they determine how the bag is handled by forklifts or cranes. This is where we start to see different categories emerge, such as the 1 and 2 loop FIBC and the more common 4 loop FIBC bags. Understanding these differences is the first step in optimizing your bulk material handling process.

Why Should You Consider 1 and 2 Loop FIBC Bags?

For many procurement managers, the standard 4 loop FIBC bags are the default choice. However, focusing only on them means you might be missing out on the unique advantages that 1 and 2 loop FIBC bags offer. These bags are designed for specific operational efficiencies, particularly in scenarios where speed and automated handling are paramount. The single or double lifting points allow for quicker attachment and detachment from machinery, which can significantly cut down on labor time and costs.

The main benefit of a one and two loop FIBC design is its simplicity and cost-effectiveness. Fewer loops mean less material and less sewing, which can translate into a more competitive price point—a key concern for any business owner. This type of FIBC bag usually has the loops formed from an extension of the bag’s main fabric, creating an integrated, strong structure. This construction makes these bags perfect for light-to-medium weight materials, often seen in the agriculture and fertilizer industries.

Furthermore, 2 loop FIBC bags usually accommodate different handling equipment than their 4-loop counterparts. They are often handled with a single hook or a specialized forklift attachment, which can be ideal for certain automated filling and discharging systems. The decision between these bags frequently comes down to the existing infrastructure at the filling and end-user facilities. For a business that supplies various customers, offering the option of a two loop FIBC bulk bags can be a competitive advantage, showing that you can cater to diverse operational needs.

A Closer Look: What are the Detail Features of 1 & 2 Loop FIBC Bags?

When we examine the detail features of 1 and 2 loop bags, we see a focus on streamlined design. The loops are a continuation of the bag’s body, often reinforced with extra fabric bands or sleeves for added strength. This integrated loop design minimizes stress points, creating a surprisingly robust container. These loop FIBC bags are built to be handled efficiently.

Let’s break down the typical features you’ll find:

- Lifting Loops:

- 1-Loop: A single, strong point of connection, ideal for automated systems where a crane or hoist can quickly grab, lift, and release the FIBC bag.

- 2-Loop: Two loop FIBC bags work similarly to 1 loop versions but offer better stability during lifting, preventing excessive swaying.

- Body Construction: The bulk bags are mostly made from circular woven polypropylene fabric. This seamless design eliminates side seams, which are traditionally weaker points in a bag, providing superior strength and resistance to sifting.

- Top and Bottom Options: Just like other FIBCs, these bags offer customization. Common options include:

- Open Top / Flat Bottom: The simplest and most economical design.

- Filling Spout / Discharge Spout: For controlled, dust-free filling and emptying.

- Liners: An internal polyethylene liner can be inserted to protect products from moisture, contamination, or to contain very fine powders. This is a critical feature for food-grade or chemical applications.

The special qualities provided by 1 and 2 loop bags make them an excellent choice for high-volume, repetitive tasks. Their design is a perfect example of how a small change—reducing the number of loops—can lead to significant gains in operational speed and cost savings.

How are These FIBC Bags Constructed for Maximum Durability?

As a manufacturer, I can tell you that the durability of an FIBC bag begins long before it’s sewn together. It starts with the raw materials. The woven polypropylene in making FIBC bags – is strong, but its quality can vary. We insist on using 100% virgin polypropylene resin, which ensures higher tensile strength and UV resistance compared to recycled materials. This is a non-negotiable point for any buyer concerned with product integrity.

The construction process itself is a science. For 1 and 2 loop FIBC bags, the body is typically woven on a circular loom, creating a seamless tube of fabric. This is a huge advantage as it eliminates vertical seams, which are potential failure points under heavy load. The loops themselves are then formed from the fabric at the top, often with a colorful wrap-around sleeve that makes it easier for equipment operators to see and grab. Every seam, especially around the base and any spouts, is sewn with high-strength, multifilament yarn using specialized stitches like the "safety stitch" and "chain stitch" to prevent unraveling.

Finally, every FIBC bag we produce undergoes rigorous testing. This isn’t just a casual inspection. We perform top lift tests, drop tests, and cyclic load tests to ensure each FIBC bag meets or exceeds the required Safe Working Load (SWL) and Safety Factor (SF), typically 5:1 for single-use bags or 6:1 for multi-use bags. These rigorously tested and designed bulk containers give you, and your customers, peace of mind.

What are the Most Versatile Uses of 1 & 2 Loop FIBC Bags?

The versatile uses of 1 and 2 loop bags are sometimes underestimated. While they excel in certain niches, their application is broader than many think. Their ability to be handled quickly makes them a favorite in industries where time is money.

Here are some of the primary sectors where these loop FIBC bags are useful instruments:

- Agriculture: This is the largest market. They are used for packaging seeds, grains, animal feed, and fertilizers. The speed of handling is a major plus during busy planting and harvesting seasons.

- Chemicals: For non-hazardous, free-flowing powders and granules, these bags are ideal. When fitted with a liner, a FIBC bag provides excellent protection against moisture and contamination.

- Construction: Transporting materials like sand, gravel, and small aggregates is another common use. The durability of the FIBC bag is essential for handling these abrasive materials.

- Recycling: These bags are perfect for light-weight, bulky materials like plastic flakes or shredded paper, helping to streamline collection and transport.

The key takeaway is that if you have a high-volume operation with semi-automated or fully automated filling lines, 1 and 2 loop FIBC bags can offer a significant return on investment. The ability to economically handle the bulk materials in these sectors makes this type of FIBC a smart logistical choice.

How Do You Choose the Right FIBC: A Comparison of 1, 2, and 4 Loop Bags?

Choosing criteria for 1, 2, or 4 loop bags depends entirely on your specific needs and the handling equipment available at both the loading and unloading points. There is no single "best" option; there is only the right FIBC for the job. As a procurement officer, making the right choice is crucial for efficiency and safety.

Let’s break down the decision-making process in a simple table:

| Feature | 1 & 2 Loop FIBC Bags | 4 Loop FIBC Bags |

|---|---|---|

| Primary Advantage | Speed of handling, lower cost | High stability, versatility |

| Handling Equipment | Single hook crane, specialized forklift | Standard forklift tines, multi-hook cranes |

| Best For | Automated, high-volume operations | General purpose, semi-manual handling |

| Load Capacity | Typically 500kg – 1000kg | Typically 500kg – 2000kg+ |

| Stability | Good, but can sway more | Excellent, very stable during lift |

| Cost | Generally more economical | Standard market price |

To choose the right fibc, you must ask the right questions. What kind of forklift does your end-user have? Is the filling process automated? How much weight does each bulk bag need to hold? 4 loop bulk bags are typically used for heavier loads and when stability is the absolute top priority. In contrast, 2 loops fibc bags offer a compelling alternative for faster-paced environments. Ultimately, selecting the appropriate fibc bag type is a conversation that should involve you, your supplier, and your end customer.

We find that many of our clients in North America and Europe, who supply the agricultural sector, benefit from offering both 1 or 2 point lifting FIBC Jumbo bags and traditional 4-loop bags. This flexibility makes them a more valuable partner to their customers.

What are the Proper Procedures for Handling 1 & 2 Loop Bags Safely?

Safety is the most important aspect of bulk material handling. The proper procedures for handling 1 and 2 loop bags are critical to preventing accidents and ensuring product integrity. While these bags are designed for efficiency, that speed must never compromise safety. FIBC safety and integrity must be the priority at all times.

Here are some essential handling guidelines:

- Always Use the Correct Equipment: Never lift a 1 or 2 loop FIBC bag with a single forklift tine. Use a proper lifting hook or a specialized attachment designed for this purpose. The lifting device should be free of sharp edges or burrs that could damage the loops.

- Inspect Before Lifting: Before every use, visually inspect the FIBC bag for any cuts, tears, or damaged stitching. Pay close attention to the lifting loops. If any damage is found, do not use the bag.

- Lift Smoothly: Avoid jerky or rapid movements when lifting. Lift the bag vertically and ensure it is clear of any obstructions. Never allow personnel to stand underneath a suspended bulk bag.

- Ensure Stability: While 2 loop FIBC bags are more stable than single-loop versions, ensure the load is balanced. When placing the bag, make sure it is on a stable, level surface.

- Adhere to SWL: Never exceed the Safe Working Load (SWL) printed on the bag’s label. This is the maximum weight the FIBC bag is tested and designed bulk bags to carry safely.

Following these rules will help increase the longevity of 1 and 2 loop FIBC bags (for multi-trip bags) and, more importantly, protect your team and your product. Proper handling is a shared responsibility between the manufacturer, the distributor, and the end-user.

What are the Latest Patterns and Advancements in FIBC Technology?

The world of industrial packaging is not static. There are always patterns and advancements in FIBC technology aimed at improving safety, efficiency, and sustainability. As a forward-thinking partner, it’s my job to stay ahead of these trends for clients like you. The advancements in fibc technology centered on efficiency and safety are particularly exciting.

One of the most significant recent developments is in anti-static technology. For industries handling fine, flammable powders, the risk of a static discharge is a major concern. This has led to the development of Type C and Type D FIBC bags. A Type C Conductive FIBC Bulk Bag has interwoven conductive threads that must be grounded during use, safely dissipating any static charge. This is a critical innovation for chemical and pharmaceutical companies.

Another area of innovation is in liners. We’re seeing more advanced form-fit liners and baffle liners that help a FIBC bag maintain a square shape, improving stability and optimizing shipping space in trucks and containers. The material science of the bags is also being improved, with stronger, lighter-weight fabrics and coatings that offer better protection against UV rays and moisture. As we look to the future, the use of 1 and 2 loop FIBC bags are expected to become even more integrated with robotic and automated logistics systems.

Beyond the Product: How to Verify Supplier Quality and Certifications?

This is a topic I know is a major pain point for buyers in the USA and Europe. You find a supplier online, the price is right, but how do you really know they are who they say they are? How can you trust their quality and their certificates? This is where experience and diligence pay off.

First, ask for a virtual factory tour. In today’s world, any reputable manufacturer should be happy to walk you through their production lines via a video call. You can see the machinery, the quality control stations, and the working conditions. This is a simple step that can reveal a lot. Second, when it comes to certifications like ISO 9001 (for quality management) or BRC (for food safety), don’t just accept a PDF. Ask for the certification number and the issuing body. You can then verify it independently on the certifier’s website. This simple check can expose fraudulent documents.

Communication is also a key indicator. Is your sales representative knowledgeable, or are they just a salesperson? Can they answer technical questions about fabric weight, UV inhibitors, and stitch types? Or do they need to "ask an engineer" for every detail? Inefficient communication is a red flag. You need a partner who can provide clear, accurate information quickly. This is where an experienced factory like ours, accustomed to dealing with the high standards of international clients, can make a huge difference. These FIBC bulk bags are indispensable due to their role in global trade, and their quality must be verifiable.

Finding a True Partner for Your FIBC Bag Storage Needs

Ultimately, buying a FIBC bag is not just a transaction; it’s the start of a partnership. You need more than a supplier; you need a partner who understands your business, your customers’ needs, and the challenges you face. This partner should be a source of expertise, providing guidance on the right type of fibc for a new product or suggesting a cost-saving design modification.

The ideal partner for your FIBC bag storage needs is a factory, not just a trading company. A factory has direct control over quality, production schedules, and raw material sourcing. This eliminates layers of miscommunication and gives you a direct line to the people making your product. When you speak with me, you are speaking with the factory. This direct relationship is crucial for solving problems quickly and efficiently. For example, if you need a shipment expedited for a key customer, we have the flexibility to adjust production schedules—a luxury a simple trading agent doesn’t have.

Whether you are in the market for standard 4 loop bulk bags, specialized PP Woven Jumbo Bag Baffle Formed Liner, or efficient 1 and 2 loop fibc bags, look for a supplier who invests in the relationship. A good partner will ask questions about your end-users, your logistics, and your goals. They will see your success as their success. This is the philosophy we’ve built our business on, and it’s how we’ve built lasting relationships with clients around the world.

Key Takeaways

To conclude this guide to jumbo bags and their uses, here are the most important points to remember:

- 1 and 2 Loop FIBCs are a specialized tool: They are not a replacement for 4-loop bags but offer significant speed and cost advantages in high-volume, automated environments.

- Construction is key: Always prioritize suppliers who use 100% virgin polypropylene and can demonstrate robust quality control and testing procedures for every FIBC bag.

- Safety is non-negotiable: Ensure everyone in your supply chain understands and follows the proper handling procedures. Never exceed the Safe Working Load.

- Ask the right questions: Choosing the appropriate FIBC bag type requires a clear understanding of your own, and your customers’, handling capabilities and needs.

- Verify your supplier: Go beyond the sales pitch. Request virtual tours, independently verify certifications, and gauge the technical expertise of your contact.

- Seek a partnership, not just a product: A direct relationship with a factory provides transparency, quality control, and the flexibility you need to serve your customers effectively. These bags give an effective solution for the transportation and storage of bulk goods.

Post time: Jul-21-2025