Hello, I’ve spent years understanding the ins and outs of industrial packaging. If you’re a business owner or procurement officer like our typical customer, Mark Thompson from the USA, you know that the devil is in the details. When you’re shipping tons of agricultural products, minerals, or chemicals, one question comes up more than any other: "Is this bulk bag really waterproof?" This article is for you. We will dive deep into the world of woven polypropylene, demystifying what "waterproof" truly means in our industry. You’ll learn the difference between water-resistant and waterproof, how the fabric is made, and what you, as a buyer, need to look for to protect your valuable cargo.

What Exactly is Woven Polypropylene Fabric?

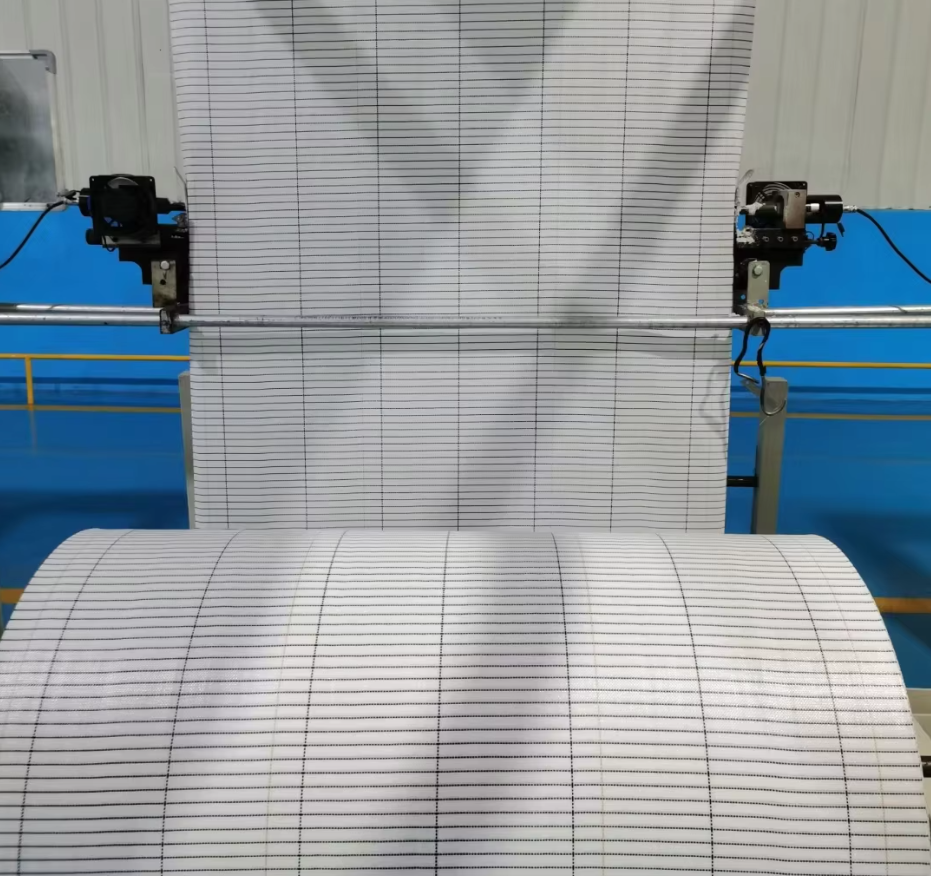

At its core, woven polypropylene is a remarkable material. It starts as a thermoplastic polymer called polypropylene (PP), a type of plastic known for its strength, durability, and resistance to many chemical solvents. To create the fabric for a bulk bag, we begin with polypropylene resin. This resin is melted down and extruded into thin, flat tapes or threads. These polypropylene threads are then loaded onto massive looms and woven together, much like you would weave cotton cloth, but on an industrial scale. This process of interlocking threads in two directions (warp and weft) is what gives the woven polypropylene fabric its incredible tensile strength and puncture resistance.

This tightly woven fabric forms the foundation of all standard pp bag products. The result is a flexible yet incredibly robust material that can hold weights exceeding 2,000 kg (over 4,400 lbs) while weighing only a few kilograms itself. The nature of this woven poly material is what makes it ideal for heavy-duty applications. It’s not just a simple plastic bag; it’s an engineered solution designed for the rigors of global shipping and handling. The properties of polypropylene make it lightweight, non-toxic, and resistant to degradation, which is why you see it used for everything from agriculture to chemical transport.

The polypropylene material itself is a marvel of modern chemistry. As a thermoplastic, it can be melted and reformed, which plays a crucial role in its manufacturing and recyclability. The base polypropylene cloth has a unique texture—strong and slick, yet pliable. When you see a large white sack holding grain or cement, you are almost certainly looking at a product made from woven polypropylene. This foundational fabric is the canvas upon which we build more advanced features, including the all-important waterproof capabilities that are critical for protecting sensitive goods.

Is Polypropylene Inherently Waterproof or Just Water-Resistant?

This is the million-dollar question for many procurement managers. The answer requires a subtle but important distinction: the base polypropylene material is waterproof, but the woven fabric made from it is initially only water-resistant. Think of it this way: a solid sheet of plastic is a complete barrier to water. However, when we weave those thin tapes of PP together, we create a super-strong fabric, but there are microscopic gaps between the woven threads. These gaps are tiny, but they can allow moisture to seep through under pressure or with prolonged exposure.

So, an uncoated woven polypropylene bag will shed water very effectively—a light rain shower won’t be a problem. The fabric is water-repellent. However, it is not completely waterproof. For many applications, this level of water resistance is perfectly adequate. For example, transporting gravel or sand, where a little moisture isn’t a concern. But for products like cement, sugar, or sensitive chemical powders, which can be ruined by dampness, this basic level of protection is not enough. The term polypropylene is waterproof refers to the raw material, not the initial woven product.

This distinction between waterproof and water-resistant is crucial. Water-resistant means the material can resist the penetration of water to some degree, but not entirely. Waterproof means it is impervious to water. Many suppliers might use the terms interchangeably, but as a discerning buyer, it’s a detail you must clarify. A standard pp bag without any treatment offers a good level of water resistance, but to achieve a truly waterproof solution, we need to take an additional manufacturing step. This is where lamination and liners come into play, transforming a water-resistant bulk bag into a waterproof fortress for your goods.

How are Woven PP Bags Made to be Waterproof?

To elevate a woven polypropylene bag from water-resistant to waterproof, manufacturers like us employ a process called lamination or coating. This is the most common and effective method. During this process, a thin layer of molten polypropylene or polyethylene (poly) is applied to the fabric. This coating fills and seals all the minuscule gaps in the weave, creating a solid, impenetrable barrier against moisture. The laminate essentially transforms the breathable woven material into a non-porous surface.

The process is precise. The woven polypropylene fabric is fed through rollers while a heated sheet of plastic film is bonded to it. This creates a composite material that retains the strength of the weave and adds the waterproof properties of a solid sheet. The coating is typically applied to the inside of the pp bag to protect it from being scuffed or damaged during handling. This ensures the integrity of the waterproof barrier remains intact. This laminated fabric is then cut and sewn into the final bulk bag.

Another method involves using a separate internal liner, which we’ll discuss more later. But for the bag itself, lamination is key. This simple addition of a laminate layer is what allows a woven pp bag to be confidently marketed as waterproof. The coating can vary in thickness depending on the required level of protection. For our clients in the food and pharmaceutical industries, this process is non-negotiable. It guarantees that their products arrive at their destination as dry as when they left our factory. This technique creates a true waterproof fabric from the already robust woven polypropylene.

What’s the Difference Between Woven and Non-Woven Polypropylene?

As a buyer, you might encounter the terms woven and non-woven polypropylene, and it’s important to understand the difference. While both are made from the same thermoplastic resin known as polypropylene, their construction and applications are worlds apart. As we’ve discussed, woven polypropylene is made by weaving PP tapes together into a strong, grid-like sheet. This gives it exceptional load-bearing strength, making it the only choice for FIBC bags (Flexible Intermediate Bulk Containers) or bulk bag products.

Non-woven polypropylene, on the other hand, is not woven. Instead, the polypropylene fibers are bonded together through heat, chemicals, or pressure. This creates a soft, cloth-like material. You’ve almost certainly encountered non-woven fabric in your daily life. It’s the material used to make those reusable shopping bags, surgical masks, and disposable gowns. The non-woven polypropylene fabric is breathable, soft, and less expensive to produce for certain applications, but it lacks the immense structural strength of its woven counterpart.

Here’s a simple breakdown:

| Feature | Woven Polypropylene | Non-Woven Polypropylene |

|---|---|---|

| Construction | Threads are woven together | Fibers are bonded together |

| Strength | Extremely high tensile strength | Moderate strength, tears more easily |

| Primary Use | Bulk bags, industrial sacks, container liners | Shopping bags, disposable apparel, filters |

| Texture | Grid-like, slightly coarse | Soft, cloth-like |

| Waterproofing | Water-resistant; becomes waterproof with lamination | Water-resistant; can be treated but not for heavy-duty waterproof needs |

Understanding this distinction is key. If a supplier offers you non-woven polypropylene bags for transporting 1,000 kg of product, you should be very cautious. For industrial bulk transport, only woven pp bags provide the necessary safety and durability. The two materials, woven and non-woven fabrics, serve entirely different markets and purposes.

Can You Get a Completely Waterproof Bulk Bag for Sensitive Materials?

Yes, absolutely. For clients who require the highest level of moisture protection, a standard laminated bulk bag is often just the first line of defense. To achieve a completely waterproof solution, we recommend using a polyethylene (PE) liner inside the woven polypropylene bag. This creates a "bag-in-a-bag" system that offers redundant protection against moisture, contamination, and oxygen. These liners are a specialty of ours, as seen in products like our Baffle Bulk Form Fit PE big bag liner.

These liners are made from a seamless tube of plastic and can be designed to perfectly fit the dimensions of the outer pp bag. They can be loosely inserted, glued in, or sewn into the seams of the bulk bag to prevent them from shifting during filling or discharge. The liner provides a hermetic seal, protecting the contents from any external elements. This is the gold standard for transporting hygroscopic products (materials that readily absorb moisture from the air), such as fine chemicals, food ingredients, and pharmaceuticals.

So, when Mark Thompson needs to ship a container of high-grade chemical powder that cannot tolerate any humidity, we don’t just offer him a laminated pp bag. We engineer a complete solution: a heavy-duty, laminated woven polypropylene outer bag with a form-fit inner PE liner. This combination ensures that even in the most humid shipping conditions, his product remains pristine. This is how we provide a truly waterproof bulk solution, moving beyond simple water resistance to total product integrity.

Why is a Laminated Polypropylene Bag the Top Choice for Bulk Transport?

A laminated polypropylene bag has become the industry standard for bulk transport for several compelling reasons. First and foremost is the unmatched combination of strength and low weight. A bulk bag designed to carry a ton of material weighs only a few pounds, dramatically reducing shipping costs compared to rigid containers like drums or barrels. The woven polypropylene provides the muscle, while the thin laminate layer adds crucial protection without adding significant weight or bulk.

Secondly, the protective qualities are superb. The laminate not only makes the polypropylene bag waterproof but also creates a barrier against dust, dirt, and other contaminants. This is vital for maintaining the purity of the product inside. Furthermore, the laminated surface is smoother, which can aid in the complete discharge of sticky or fine materials, reducing product waste. For companies in the agriculture and food sectors, this ensures their products arrive clean and uncontaminated. Many food-grade bulk bags, like those used for soybeans or coffee, rely on this technology. You can see examples in our Food Grade Dry Bulk Container Liner For Soybeans.

"In logistics, every gram of weight and every cubic centimeter of space matters. Woven polypropylene bags offer the most efficient strength-to-weight ratio in the industry, and lamination makes them a fortress against the elements." – Logistics Industry Maxim

Finally, cost-effectiveness and versatility seal the deal. Woven polypropylene bags are significantly cheaper to produce than rigid alternatives. They can also be folded flat when empty, saving immense space in warehouses and during return transport. Coupled with the ability to customize them with different spouts, loops, and liners, they are adaptable to nearly any product or filling/discharging system. This combination of protection, performance, and price is why the laminated polypropylene woven bags dominate the world of bulk material handling.

How Do I Verify the Waterproof Properties of a PP Bag Before a Large Order?

This is a critical step for any serious buyer and directly addresses a major pain point: ensuring quality. As a manufacturer, I respect and encourage this diligence. First, always request a sample. No spec sheet or certificate can replace having the physical pp bag in your hands. Once you have it, you can conduct a simple field test. Fill the bag with a small amount of water, seal it, and leave it for 24 hours. Check for any leaks or dampness on the exterior. You can also place the sample under a running tap to observe how the fabric repels water.

Second, ask your supplier for technical specifications on the lamination. Key details to inquire about are the coating weight (usually measured in grams per square meter or gsm) and the material used (PP or PE). A thicker coating offers better protection. Don’t be afraid to ask for documentation. Reputable bag manufacturers will have quality control reports and can provide a Certificate of Analysis for the raw materials, including the polypropylene resin. This helps you avoid the risk of certificate fraud.

Finally, clarify the testing standards they use. For instance, we test our waterproof fabric for hydrostatic pressure resistance, which measures how much water pressure the fabric can withstand before it leaks. A supplier should be able to explain their quality assurance processes. Clear communication is key. A good supplier will welcome your questions and provide transparent answers. If a salesperson is evasive or can’t provide technical details, it’s a major red flag. Your goal is to build a partnership based on trust, and that starts with verifying the waterproof properties of the polypropylene bag you intend to purchase.

Are Waterproof Bulk Bags Reusable and Environmentally Friendly?

There’s a growing focus on sustainability in every industry, and rightly so. One of the great advantages of high-quality woven polypropylene bags is that they are reusable. A well-constructed bulk bag is typically rated for a 5:1 or 6:1 Safety Factor, meaning it’s designed to hold five or six times its Safe Working Load. This inherent robustness means that, with proper inspection and handling, a bulk bag can be used multiple times in a closed-loop system, significantly reducing waste and cost per trip.

Furthermore, polypropylene is a recyclable material. At the end of their service life, bags can be recycled. They are cleaned, melted down, and the recycled polypropylene is used to create new products, ranging from plastic lumber and car parts to new, non-food-grade bags. This recyclability is a huge environmental advantage over other packaging types that are destined for the landfill after a single use.

While any plastic product has an environmental footprint, polypropylene bulk bags offer a responsible solution for industrial transport. Their efficiency (low weight for high capacity) reduces fuel consumption during shipping, and their reusability and recyclability minimize their end-of-life impact. When you choose a durable, multi-trip waterproof bulk bag, you are making a choice that is not only economically sound but also environmentally conscious.

What Customizations Enhance the Waterproofing of Woven Polypropylene Bags?

Beyond the standard lamination and liners, several customizations can further enhance the waterproof integrity of a bulk bag. The design of the top and bottom of the bag plays a surprisingly large role. For example, a spout top with a "petal" or "star" closure offers better protection than a simple open-top design. This type of closure allows the spout to be securely tied off and covered with a protective flap, preventing moisture from entering through the top opening. These features are critical for companies needing reliable PP Woven Container For Dangerous Goods where product integrity is paramount.

The seams of the pp bag are another potential point of moisture ingress. While standard seams are very secure, for ultimate protection, we can add a "filler cord" or "felt" into the seams. As the bag is stitched, this cord is sewn along with the thread. It fills the tiny holes left by the sewing needle, creating a dust-proof and highly water-resistant seal. This technique, known as sift-proofing, is an excellent way to bolster the waterproof capabilities of the bag’s construction.

Finally, the type of liner and how it’s integrated can be customized. We can offer liners made from different materials, such as aluminum foil laminates for products that are sensitive to oxygen and moisture. We can also create biaxially oriented polypropylene (BOPP) bags, where a high-gloss, printed film is laminated to the exterior. While often used for retail packaging, this layer adds another robust, waterproof layer to the fabric. Every aspect of the bulk bag, from bag closures to seam types, can be tailored to create the perfect waterproof product for your specific needs.

Choosing the Right Waterproof Bag: Key Questions to Ask Your Supplier

Navigating the world of industrial packaging can be complex, but asking the right questions can make all the difference. As a procurement officer, your job is to mitigate risk and ensure value. When speaking with a potential supplier about a waterproof bulk bag, here is a checklist of questions to guide the conversation and help you avoid common pitfalls.

- What is the coating/lamination weight on your fabric? (This tells you how thick and robust the waterproof layer is.)

- Is the bag made from 100% virgin polypropylene resin? (Virgin PP is stronger and more reliable than recycled material for heavy-duty bags.)

- Can you provide a product specification sheet and a sample for testing? (Never order without seeing and testing the product yourself.)

- What type of seam do you recommend for my product? Do you offer sift-proofing? (This shows you are thinking about details beyond just the fabric.)

- Do you recommend an internal liner for my application? If so, what kind and how is it attached? (This tests their expertise in providing a complete solution.)

- What are your quality control procedures during manufacturing? (Look for suppliers who can detail their processes, from raw material inspection to final bag testing.)

- What is your lead time, and how do you handle potential shipping delays? (This addresses a key pain point and tests their communication and logistics planning.)

By asking these targeted questions, you move the conversation from a simple price discussion to a technical evaluation. you’re not just a customer; you are a partner in quality. A supplier who can confidently and transparently answer these questions is one who has robust processes in place, respects your business needs, and is less likely to cause the shipment delays or quality issues that disrupt your entire production schedule. For Mark, and for buyers like him, this diligence is the best insurance policy against the common headaches of international procurement.

Key Takeaways: Your Waterproof Bulk Bag Checklist

As we’ve explored the world of woven polypropylene, it’s clear that not all bags are created equal. The term "waterproof" carries specific meaning, and understanding the nuances is the key to protecting your product, your budget, and your reputation. Before you make your next purchase, keep these essential points in mind.

- Understand the Base Material: The raw polypropylene material is waterproof, but the standard woven polypropylene fabric is only water-resistant due to the tiny gaps in the weave. Don’t mistake one for the other.

- Lamination is Key: The process of applying a thin laminate or coating of poly to the fabric is what seals the weave and creates a truly waterproof bulk bag. This is the most critical feature to look for.

- Liners for Ultimate Protection: For highly sensitive or hygroscopic products, a laminated outer bulk bag combined with an inner polyethylene (PE) liner provides a "bag-in-a-bag" system that is completely waterproof and hermetically sealed.

- Woven vs. Non-Woven: Remember the crucial difference. Woven polypropylene bags are engineered for the immense strength needed for industrial transport. Non-woven polypropylene is a softer, weaker fabric used for items like reusable shopping bags.

- Due Diligence is Non-Negotiable: Always request samples, technical specification sheets, and quality certifications. A simple water test on a sample can tell you more than a thousand words on a website.

- Think Sustainably: High-quality pp bag products are not single-use items. They are designed to be reusable and are made from a recyclable plastic, making them an environmentally responsible choice for modern logistics.

- Customization Matters: From sift-proof seams to specialized closures and liners, the right customizations can significantly enhance the waterproof performance of your bulk bag. Discuss these options with your manufacturer to create the perfect packaging solution.

If you need bulk bags or liners that you can trust to protect your valuable cargo from the elements, the details matter. By arming yourself with this knowledge, you can confidently navigate the market, ask the right questions, and build lasting partnerships with suppliers who prioritize quality as much as you do.

Post time: Aug-27-2025